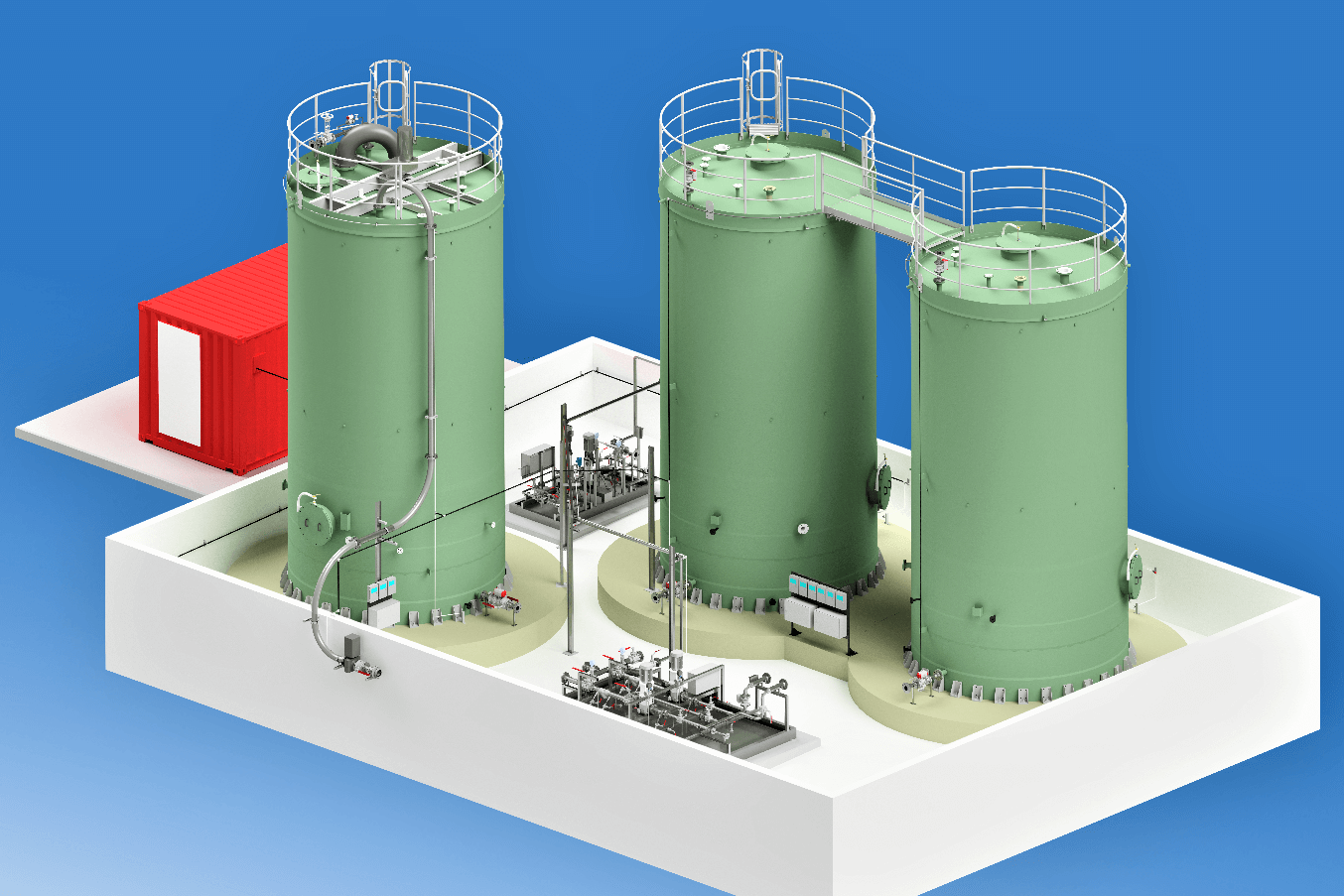

TANK FARMS FOR UREA SOLUTION AND/OR AMMONIA WATER

TANK FARMS

We plan and deliver complete storage and supply systems for ammonia, ammonia water, urea solution (urea), heating oil or other hazardous substances. Regardless of whether it is for power plants, waste incineration plants, the glass and cement industry or industrial furnaces - from 10 to over 1000 m³ - we are your partner for your tank farm including all field devices and safety-related equipment in accordance with the provisions of the WHG or country-specific regulations.

Depending on the requirements, the containers are made of a wide variety of materials, such as various stainless steels or plastics (HDPE, GRP), in single-walled or double-walled design, standing or lying as well as with or without trace heating and insulation.

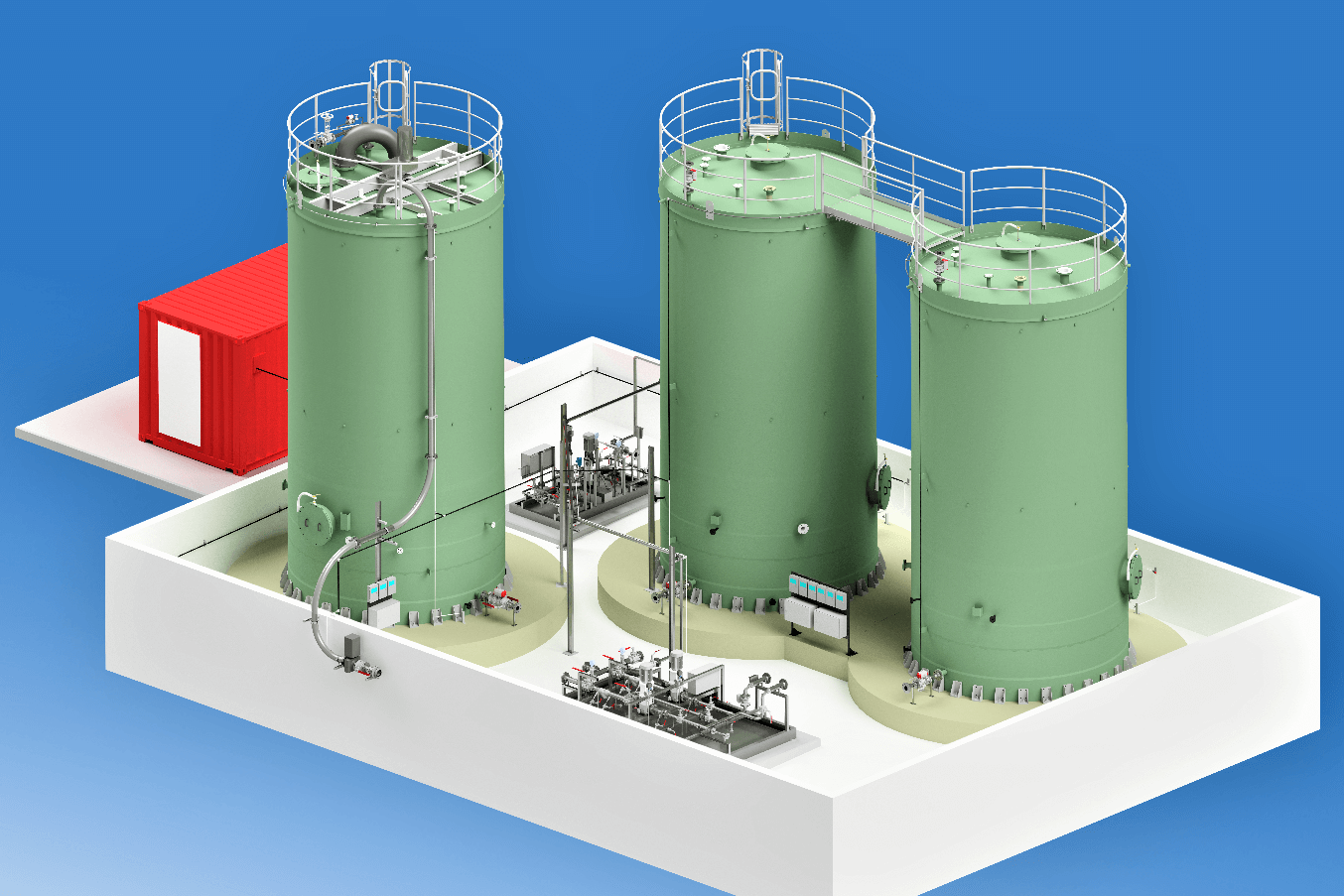

TANK FARMS FOR UREA SOLUTION AND/OR AMMONIA WATER

TANK FARMS

We plan and deliver complete storage and supply systems for ammonia, ammonia water, urea solution (urea), heating oil or other hazardous substances. Regardless of whether it is for power plants, waste incineration plants, the glass and cement industry or industrial furnaces - from 10 to over 1000 m³ - we are your partner for your tank farm including all field devices and safety-related equipment in accordance with the provisions of the WHG or country-specific regulations.

Depending on the requirements, the containers are made of a wide variety of materials, such as various stainless steels or plastics (HDPE, GRP), in single-walled or double-walled design, standing or lying as well as with or without trace heating and insulation.

STORAGE AREA FOR UREA SOLUTION AND / OR AMMONIA WATER

Storage areas for urea or ammonia water essentially consist of an unloading station and a standing or lying container including all the necessary control and monitoring instruments. The container is usually made of GRP (glass fiber reinforced plastic) or stainless steel. In the case of a single-walled version, according to the WHG, a collecting basin must also be provided, for a double-walled version this is not necessary. The media are conveyed via completely pre-assembled pump modules or, in the case of urea solution, via submersible motor pumps installed in the tank.

THE RIGHT TANK FARM FOR YOUR REDUCING AGENT

When using urea solution as the reducing agent, the container is insulated and heated when installed outdoors. This is not necessary with ammonia water.

The container is equipped with the necessary field devices and safety devices for the storage of urea solution or ammonia water. The safety devices essentially consist of a level measurement, overfill protection and leakage monitoring.

A pressure measurement and one or more NH3 detectors are available for ammonia water. In the case of ammonia water, the measurements in the container are carried out in an explosion-proof version. The container and the necessary safety devices are designed in accordance with the provisions of the WHG (Water Management Act).

UREA SOLUTION AND/OR AMMONIA WATER

For plants that are operated with urea, tanks and pipelines are insulated if necessary and equipped with trace heating in order to prevent crystallization that occurs during 45 % urea solution occur at temperatures below + 10 ° C. So that the urea solution cannot heat up too much in hot weather in summer due to the energy input from the submersible pumps, it must be ensured during the planning that the insulation of the storage tanks is designed accordingly.

The advantage of ammonia water is that there is no need for insulation and heating on the tank and on the pipelines, since the freezing point of the water decreases with the ammonia content and ammonia cannot crystallize. 25 % ammonia water has z. B. a freezing point of -57.5 °C.

UREA MIXING STATION

If urea is to be delivered in granular form or as prills, it must be mixed on site to dissolve it. Whether for bigbags or silo vehicles - we deliver turnkey unloading and mixing stations for solid urea.